Normalizing

A heat treatment process that enhances the structure and mechanical properties of steel

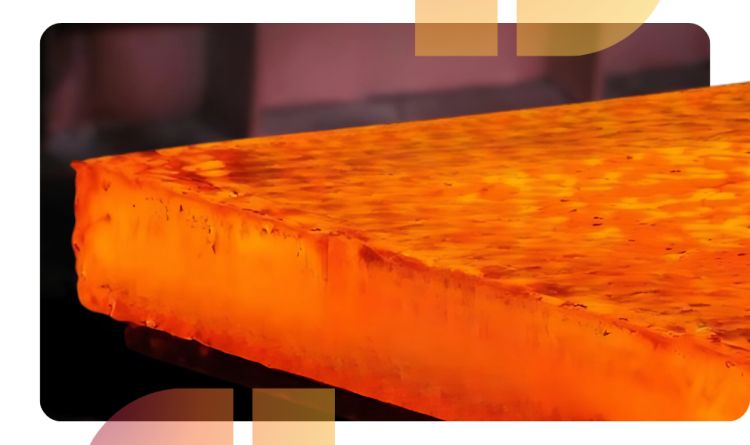

In cutting processes such as oxy-fuel cutting—especially with medium- and high-carbon steels—the heat-affected zone can be significant. For this reason, a subsequent normalizing process is essential. It involves heating the material in a furnace to approximately 850–900°C, for about one hour per inch of thickness.

This treatment is used to relieve internal stresses, improve and homogenize the structure, and enhance the mechanical properties of the material. Through this thermal process, we ensure the final quality and performance of every piece.

In cutting processes such as oxy-fuel cutting—especially with medium- and high-carbon steels—the heat-affected zone can be significant. For this reason, a subsequent normalizing process is essential. It involves heating the material in a furnace to approximately 850–900°C, for about one hour per inch of thickness.

This treatment is used to relieve internal stresses, improve and homogenize the structure, and enhance the mechanical properties of the material. Through this thermal process, we ensure the final quality and performance of every piece.